Manufacturer and Exporters of : Textile Processing Machinery : Stenter Machine

STENTER MACHINE ::::::::::

|

Special Features :::::

|

|

|

|

.............................................................................................................................................. |

||

|

Cockpit :::::

|

|

|

|

.............................................................................................................................................. |

||

|

Overfeed & Underfeed Drive :::::

|

|

|

|

.............................................................................................................................................. |

||

|

Main Chain :::::

|

|

|

|

.............................................................................................................................................. |

||

|

Pinning Unit :::::

|

|

|

|

.............................................................................................................................................. |

||

|

Chamber :::::

|

|

|

|

.............................................................................................................................................. |

||

|

Chamber Frame :::::

|

|

|

|

.............................................................................................................................................. |

||

|

Nozzle :::::

|

|

|

|

.............................................................................................................................................. |

||

|

Blower Panel :::::

|

|

|

|

Burner Panel :::::

|

|

|

|

Plaiter Unit :::::

|

|

|

|

2 Bowl Mangle :::::

|

|

|

|

2/3 Bowl Mangle :::::

|

|

|

|

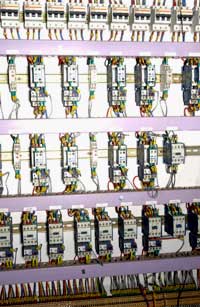

Electrical Control Panel :::::

|

|

|

|

Extra Accessories ::::: |

||

|

|

||

Plot No. 652/4, Road No. 7, GIDC,

Sachin - 394230,Surat, Gujarat, INDIA

Tel : +91-261-2399620 Fax :

+91-261-2398698 E-mail :

response@stenmech.com

Created and Hosted By : Softweb Technology