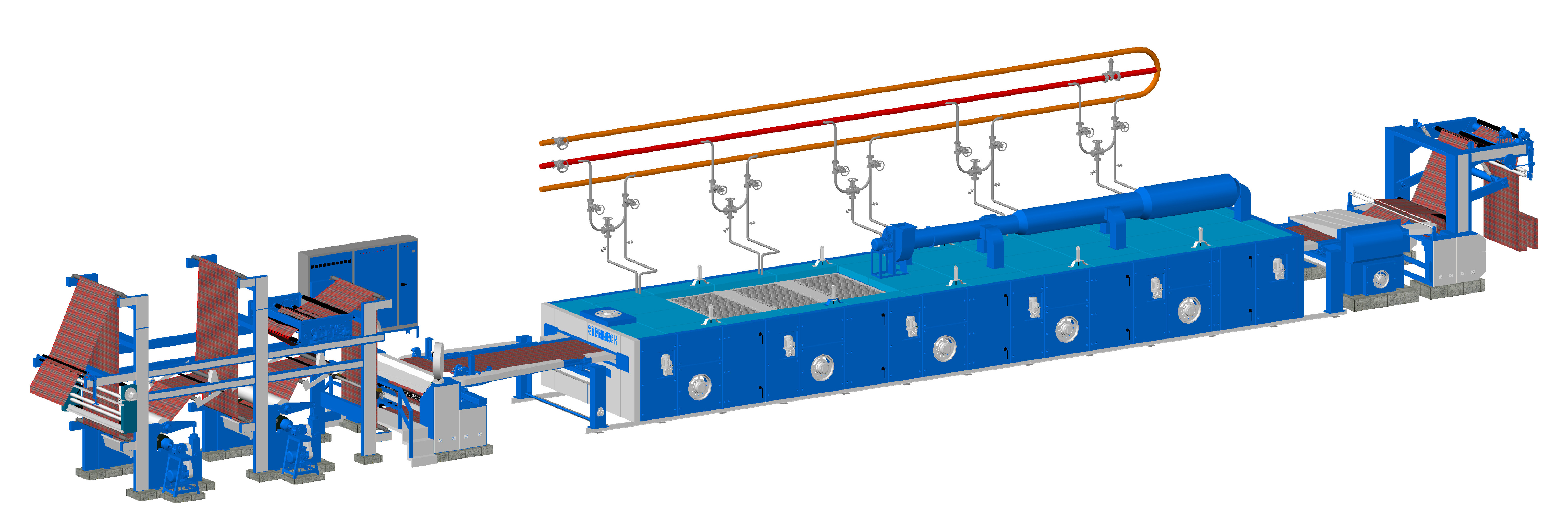

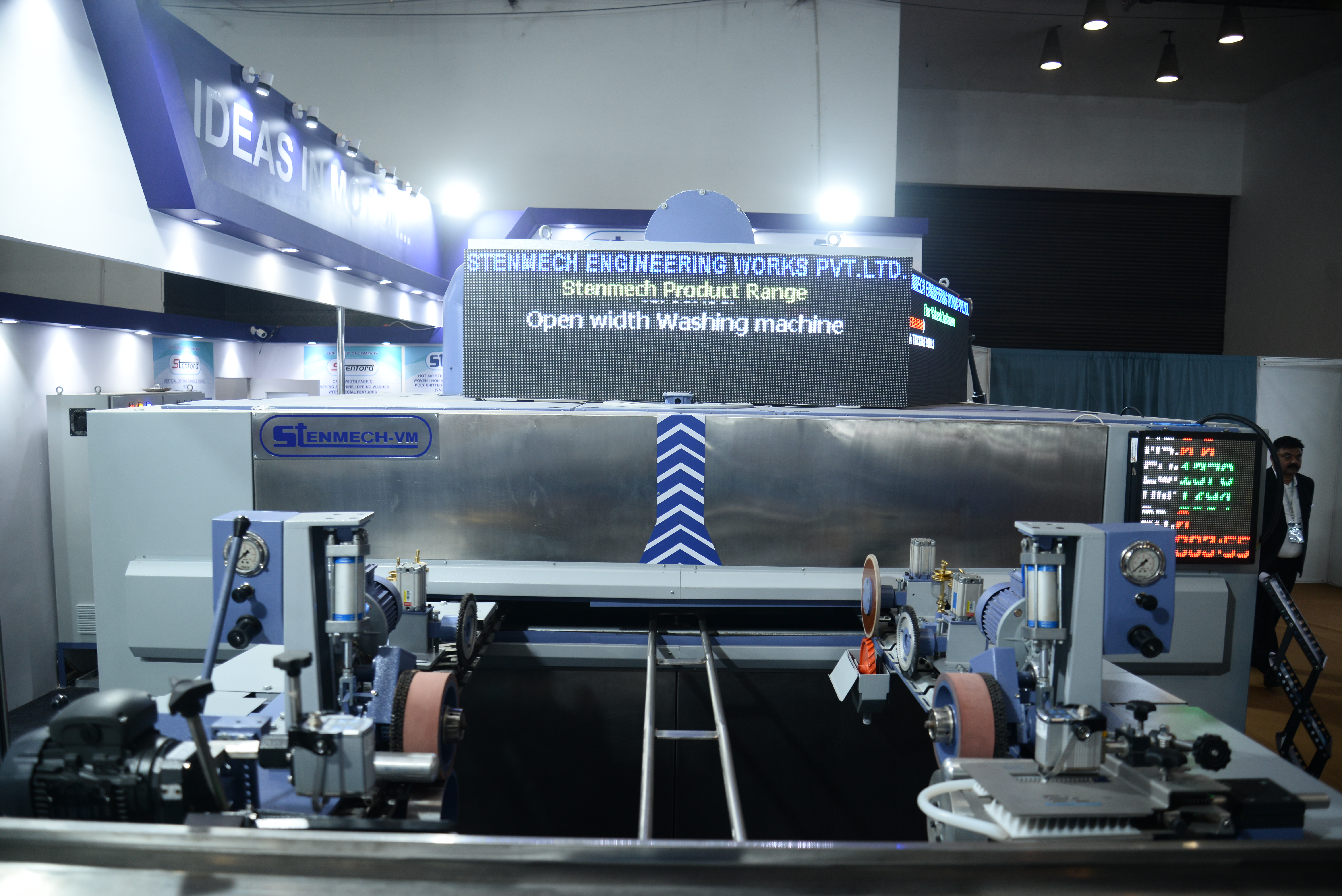

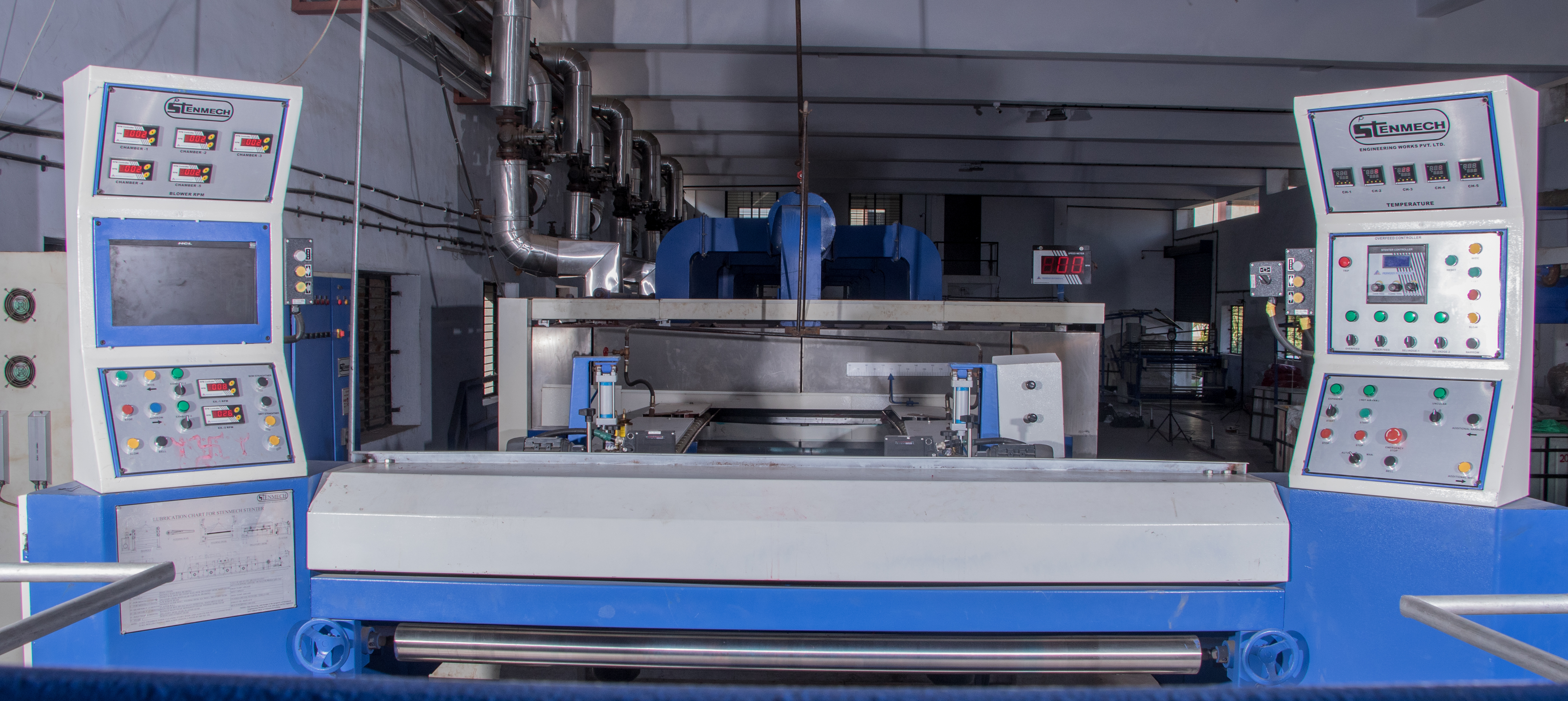

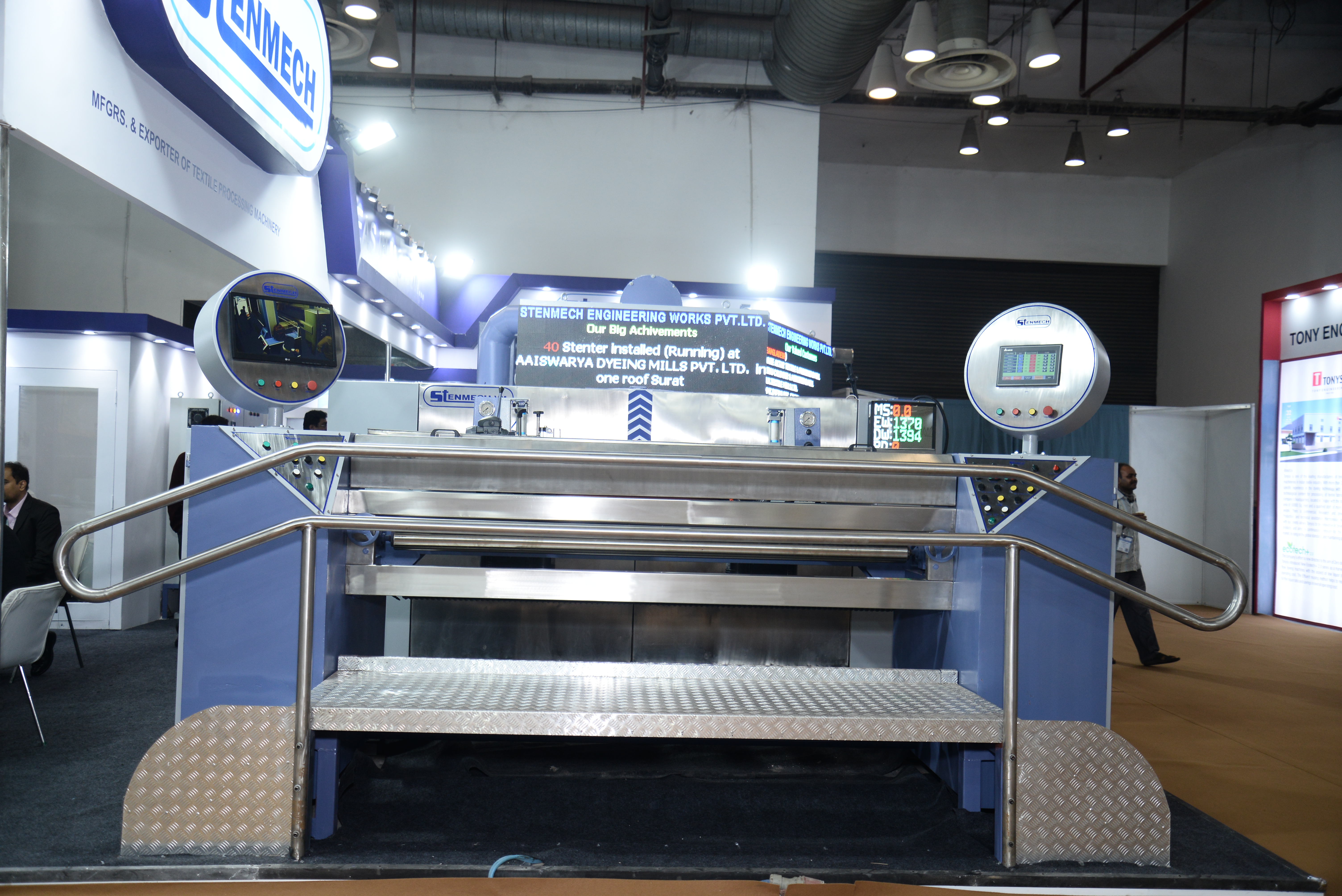

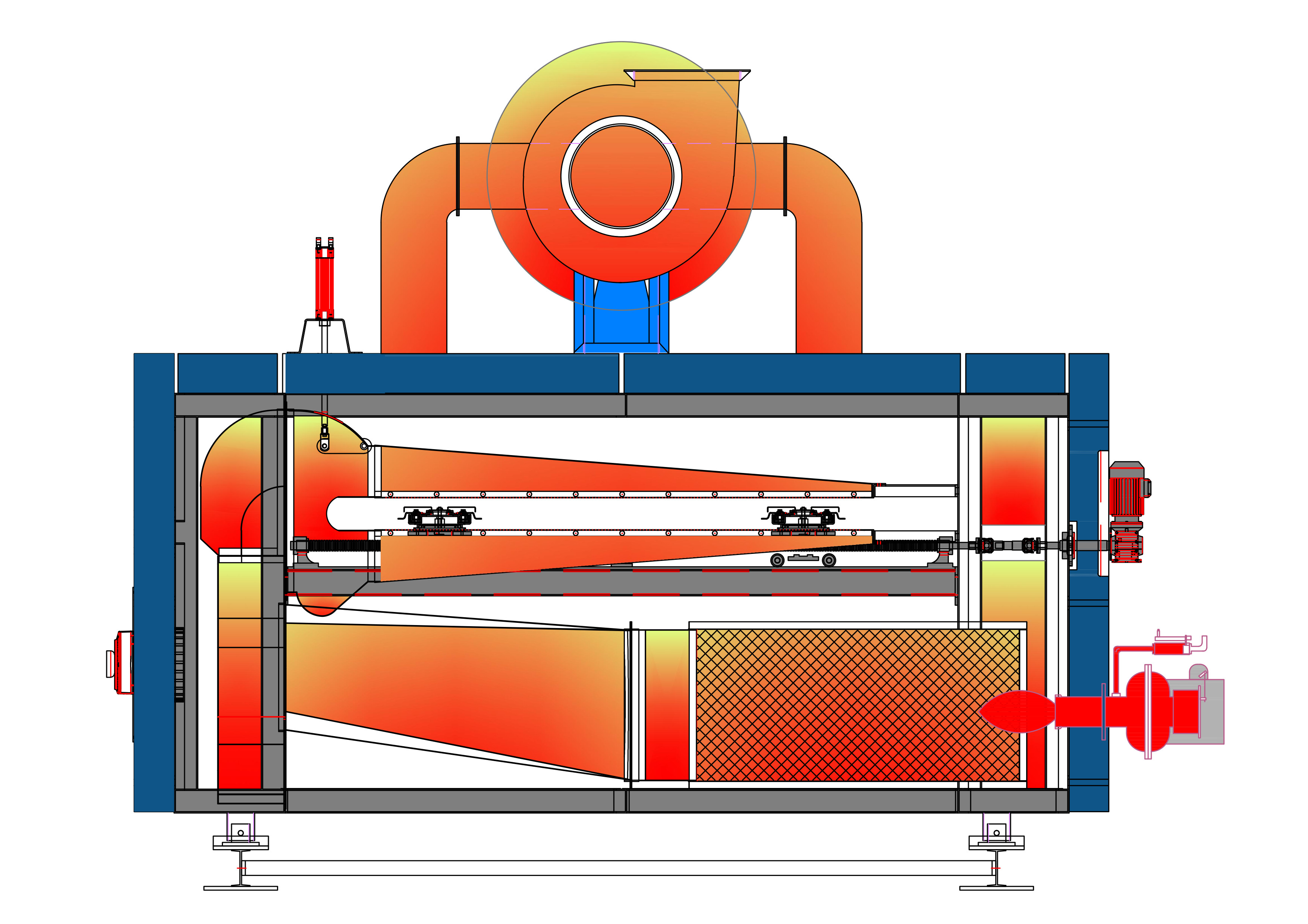

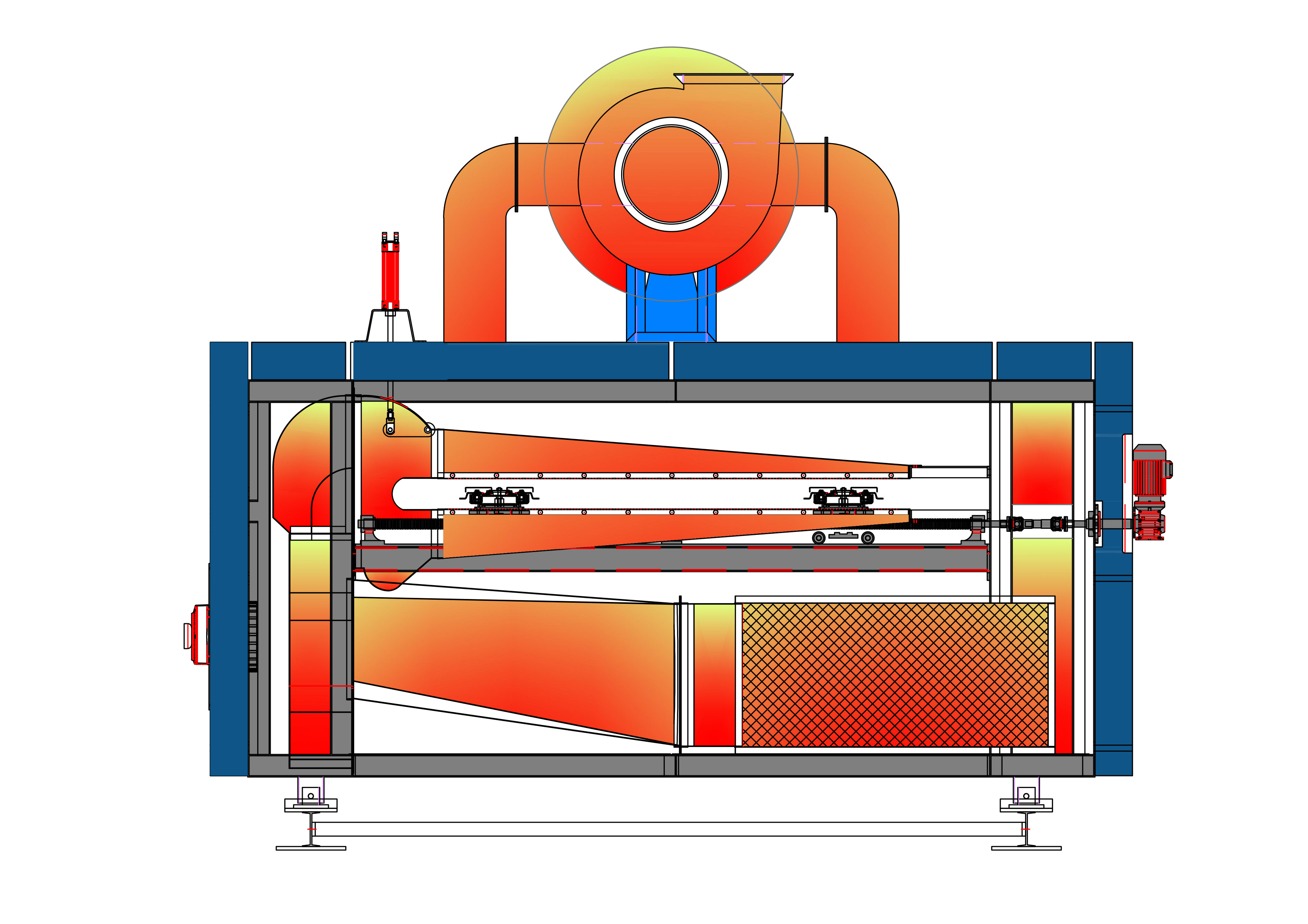

Stenmech VM-Super is an improved version specially designed to get 20% more production.This machine also offers the same production at lower electical power consumption,this quantum leap in performance is achieved with a combination of various factors - change in airflow and heat transfer,system,redesigned blowers,radiators and nozzles.

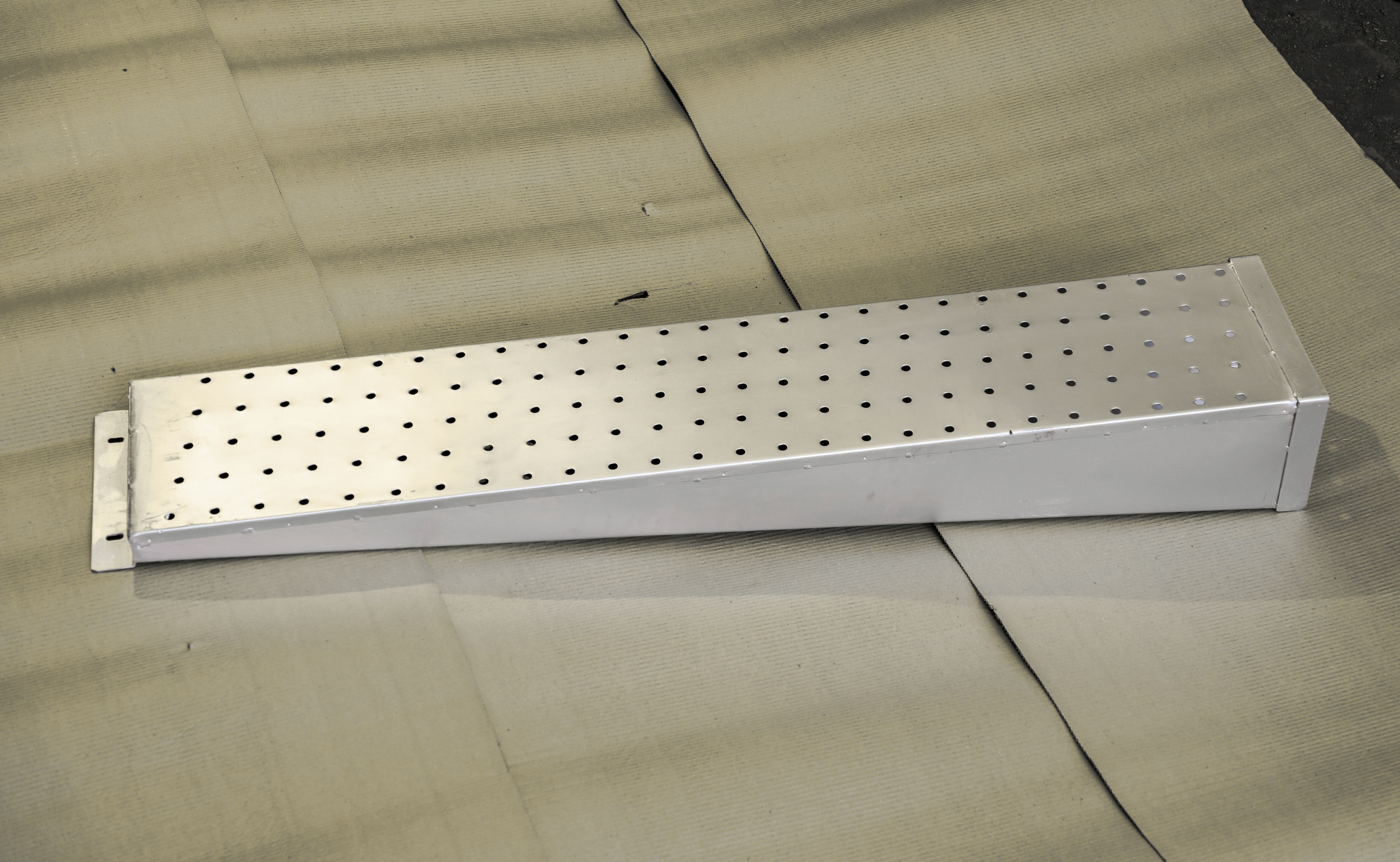

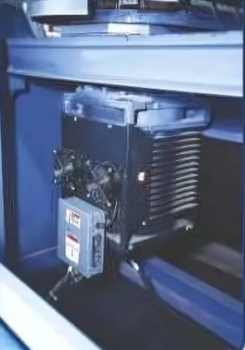

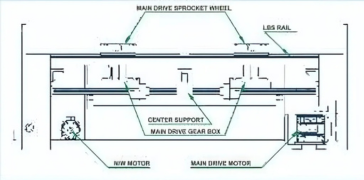

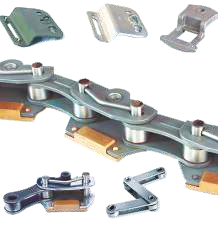

Feeding Rail length up to six meters for knitted fabric which require additional equipment like.,

(1) Gumming Device (2) Steaming Box (3) Centre Support rod and Driven Rope available on request.

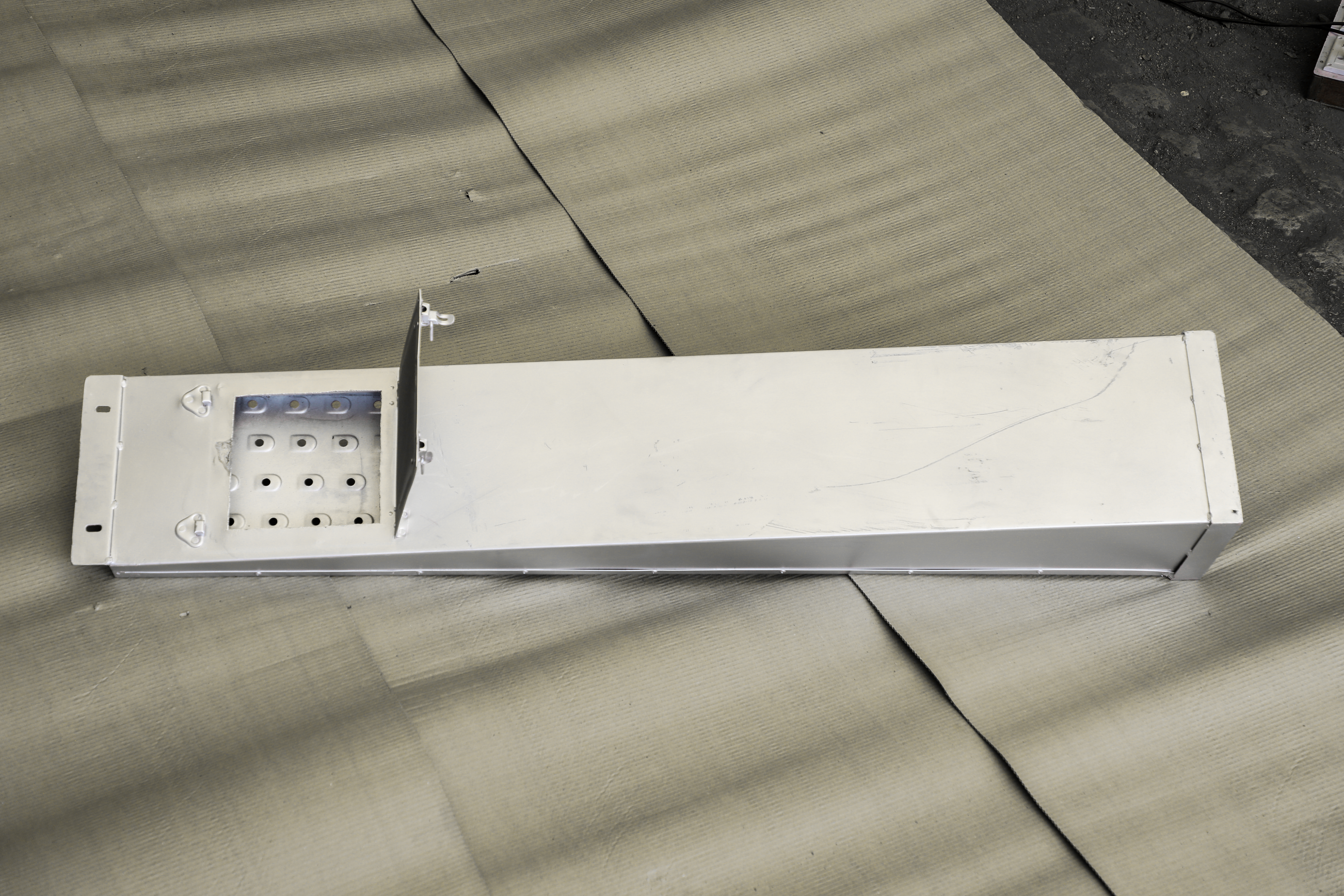

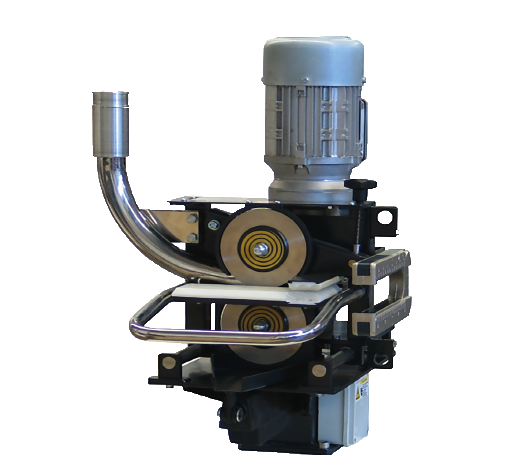

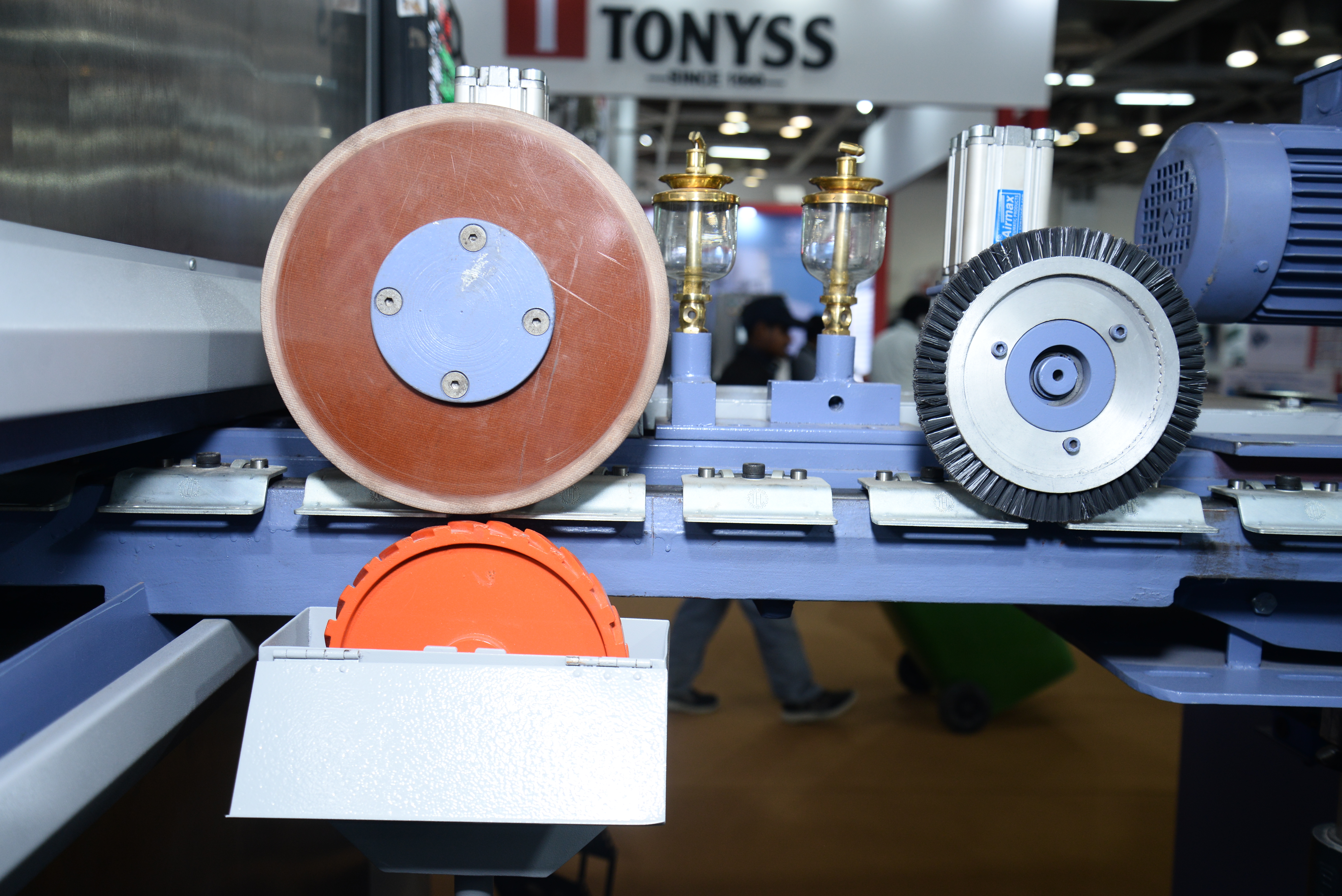

The edge trimmers are mounted at the delivery of Stenter to trim and remove the pinned edge of the web. The trimming position of the knives can be adjusted infinitely to suit various material qualities, and to get the specific edge trim required. The cut-out Selvedge is cleaned through the suction blower.

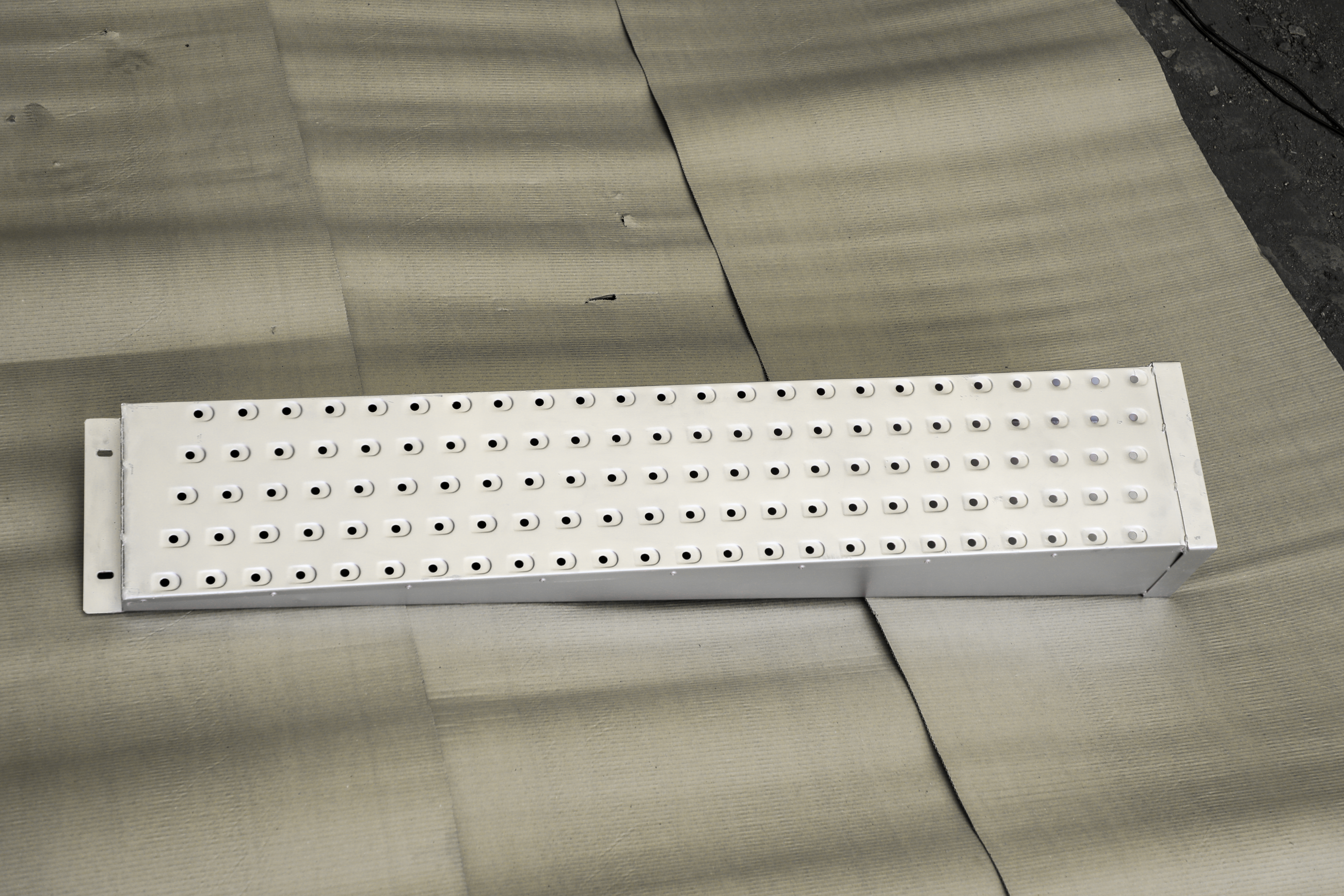

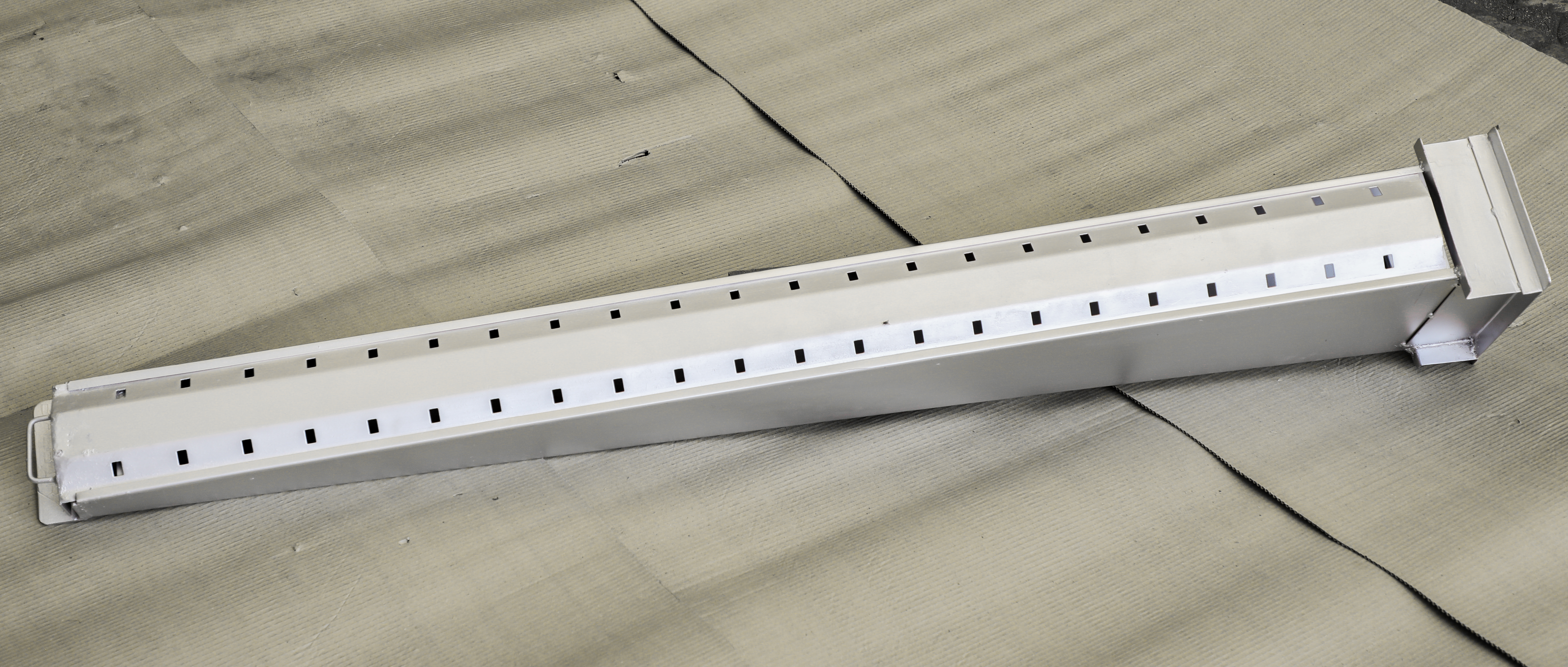

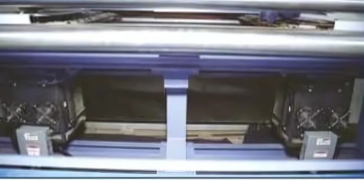

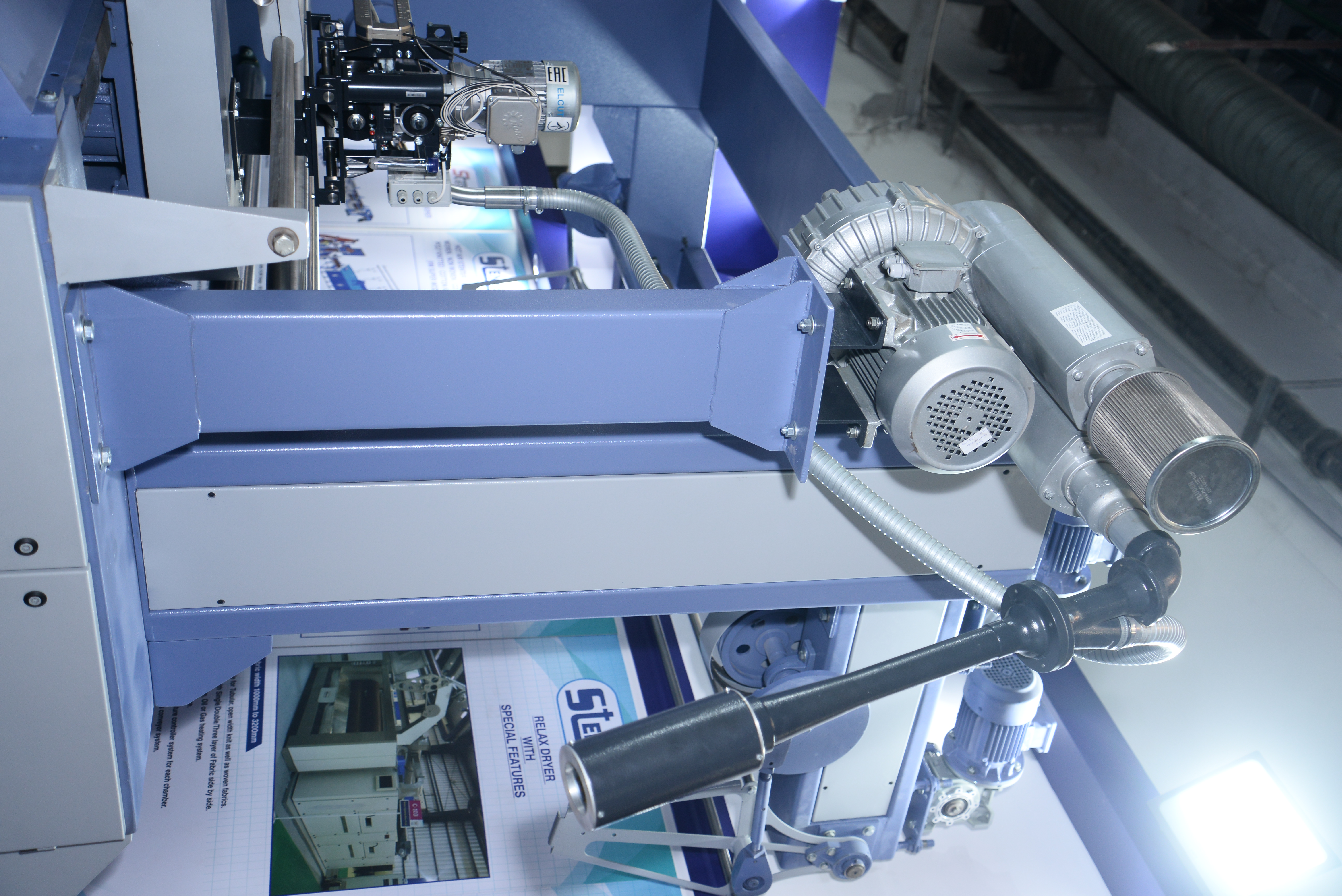

The newly design radial fans and nozzles increase the total flow of hot air inside and guarantee circulation level increase of more than 25% both. Impinging and amount of circulation of hot air optimized to result in increased productivity.